LASER SCANNING

Our design work relies strongly on 3D CAD modelling.

Chemprod is equipped with a latest generation Laser Scanner to support these activities, to optimize the field survey, and ensure the best final output to our Clients.

THE LASER SCANNER:

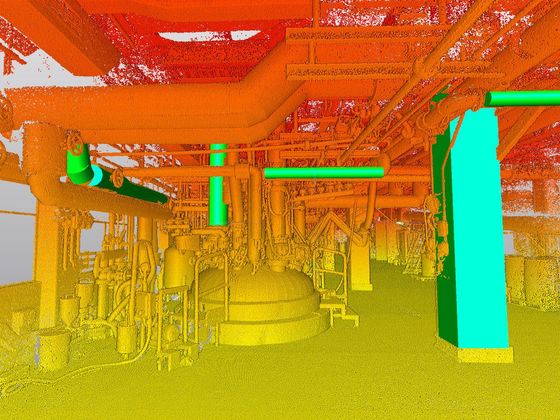

A Laser Scanner is an instrument capable of measuring the surrounding environment by detecting hundreds of thousands of points around itself.

Several surveys from different positions are then merged, by software, into a single Point Cloud that reproduces the existing structures with great detail and precision.

BENEFITS:

- Speed: precise survey of highly complex structures is possible in a very short time compared to traditional techniques;

- Accuracy and Precision: the finest details of irregular and articulated surfaces are collected;

- Wide Reach: elements with difficult access for odd positioning or for safety reasons can be measured from distance;

- Massive Sampling: much information can be extracted afterward from the cloud, without need of further field surveys.

USE CASES:

In our design work, Laser Scanning is strategic in all projects involving existing facilities, as revamping activities or new process integration. It becomes a key asset when detailed documentation of the existing plant is inaccurate, incomplete or missing. It can also be useful to identify design problems and significant discrepancies in the as-built construction.

After the field survey, the Point Cloud can be used to:

- Create detailed models of existing structures;

- Evaluate clearance and clash when inserting new elements in an existing plant;

- Linear or volumetric measurement;

- Compare Design and completed Construction;

- Perform advanced inspection of surfaces, shapes, sections, slopes.